Introduction

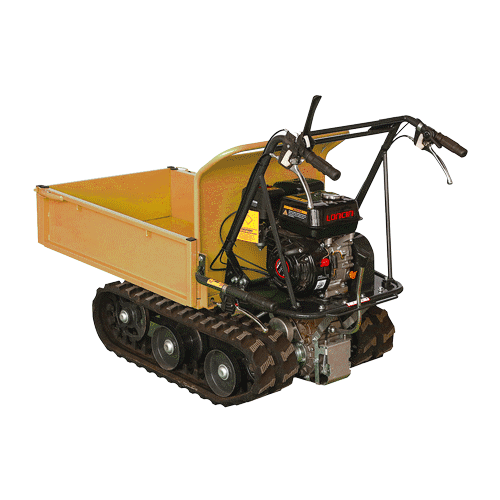

A mini dumper, also referred to as a compact utility loader or mini skid steer, is a small power machine equipped with a dump bed for hauling and unloading various materials. Mini dumpers provide maneuverability and versatility on tight worksites for handling loose aggregates, debris removal, landscaping jobs, and light-duty excavation and digging tasks.

With many sizes and configurations now available, selecting the ideal mini dumper for your specific needs deserves careful evaluation. This guide covers critical factors from lift capacity and dimensions to attachments and safety considerations as you navigate choices to boost project productivity.

Key Design and Performance Attributes

While less powerful than full-size skid steers, mini dumpers offer impressive hauling capability in more compact dimensions:

Lift Capacity – Typically 0.5 – 1.5 tons rating to handle modest loads

Tipping Height – Dump angles from 50° to over 90° to clear walls and discharge

Clearance – Integrated bucket/fork attachments with only inches ground clearance

Maneuverability – Tight turning radii under six feet through articulated steering

Traction – Optional 2WD or 4WD configurations with powerful hydraulic motors

Carefully factor required capacity and jobsite space constraints when deciding optimal size class. Purpose built design allows easy material unloading even in cramped interior spaces.

| Specification | Mini Dumper Capability |

|---|---|

| Max Lift Capacity | 0.5 – 1.5+ Tons |

| Dump Angle | 50° – 90°+ Degrees |

| Inside Turn Radius | Under 6 ft |

| Travel Speed | 0 – 7+ mph |

Choosing Attachments and Accessories

Standard built-in buckets suit most applications but a growing attachment ecosystem further boosts versatility:

- Extended buckets for added volume

- 4-in-1 fold out buckets to handle multiple materials

- Pallet forks for lifting and transporting items securely

- Power brooms for sweeper functionality

- Augers/drillers to penetrate tough terrain

- Grapples to grip awkward loads

- Lifting hooks/slings to securely hoist below the bucket

Optional canopy, road lights and specialized tires for sensitive flooring also expand customization. This mix and match modularity makes mini dumpers adaptable across nearly any activity.

Power and Control Configurations

Engine Options – Diesel and gas engines up to 45 hp dominate although electric/battery-powered variants continue emerging offering zero emissions performance.

Hydraulic Supply – Auxiliary hydraulics come standard or optional to power attachments. Can allow operation of multiple actuators simultaneously. Consider potential work tool needs when assessing requirements.

Joystick Controls – Many mini dumpers feature ergonomic joystick controls to intuitively govern bucket motion and steering through hydraulic thumbwheels and buttons for smooth precise operation.

Proper power matching ensures achieving duty cycle expectations while joystick controls grant exemplary controllability.

Evaluating Durability and Reliability

Mini dumpers perform demanding work so assessing structural life expectancy proves critical before adoption:

Load Testing – Reputable manufacturers load test units to 2-3X rated lift capacity affirming sufficient strength margin.

Stress Analysis – Finite element analysis minimizes metal fatigue through optimized component design shape/reinforcing.

Materials – Structural steel materials along with rugged pin and bushing connections ensure years of trouble-free operation even in abusive environments.

Quality Checks – Stringent manufacturing quality control protocols examine all critical areas – from weld integrity to engine performance for maximum in-service reliability.

Carefully vetting engineering validation procedures boosts confidence in system robustness over thousands of high intensity operating cycles.

Operator Safety Considerations

While powerful machines, mini dumpers provide smart integrated safety mechanisms:

- Tilt sensing valves – Lock hydraulic lift arms if the bucket elevates beyond set angles

- Interlock control circuits – Prevent unintended bucket and steering movement

- Emergency stop switch – Shut down all systems in case of a problem

- Seat sensors – Neutralize lift/drive functions if operator departs

- Backup alarms – Loud audible warning informs nearby pedestrians and workers

- Lights – Illuminate forward and rear pathways

Thoughtfully designed features supply essential protection for both equipment and user. Be sure to confirm presence of key items matching work environment needs.

Total Cost of Ownership Factors

Along with upfront machine acquisition expense, lifetime operating budgets factor heavily when assessing mini dumper value:

- Fuel/charging costs and engine maintenance

- Attachment expenses if expanding functionality

- Scheduled preventative service requirements

- Structural part replacement from wear over duty cycles

- Component rebuild/refurbishing needs after years of use

- Resale value depending on maintenance history

While not often top of mind, carefully weighing long term expenditures ensures making financially informed purchase decisions.

Conclusion & Next Steps

If enhanced maneuverability and hauling productivity across tight spaces proves important for your material handling operations, a mini dumper brings immense consolidated capability. From debris clearing to landscape supply delivery, mini dumpers affordably tackle nearly any project through value-adding attachments and versatile base utility. Use this guide’s key specification considerations to hone requirements then connect with manufacturers to match prospective models against your needs. Incorporating mini dumpers into the equipment fleet allows tackling jobs otherwise out of reach.

FAQ

What safety practices are recommended when operating mini dumpers?

Follow all manufacturer procedures, inspect equipment before use, don traffic vest for visibility, clear operation area of debris, maintain safe following distance between units, install rotating beacon if no canopy present, drive smoothly without sudden acceleration/braking, and use extreme care on inclines/ramps.

How long is the expected lifespan for a mini dumper used in landscaping applications?

With proper maintenance and structural component rebuild every 4,000-6,000 hours, expected mini dumper lifespans often exceed 8-10 years in landscaping environments before chassis wear prompts retirement. Powertrain rebuilds can further extend serviceability.

What maintenance checks are required on mini dumpers?

Daily inspections should check fuel and fluid levels, test safety systems, scan for leaking hoses/fittings, while also verifying tire pressures and attachment security. The operator manual will outline formal preventative maintenance details across intervals ranging 25 hours up to 400-500 hours depending on component and duty cycle.