Different Types of Excavators: A Comprehensive Guide.Excavators, also known as diggers or 360-degree excavators, are indispensable heavy construction equipment used for a variety of earthmoving tasks. These powerful machines offer unparalleled versatility and efficiency, making them essential for tasks like digging trenches, holes, foundations, and demolition work in the construction industry.

Different Types of Excavators are the unsung heroes of the construction industry, and understanding their different types and applications is crucial for anyone involved in construction. In this article, we’ll delve into the world of excavators, exploring various types and their unique features, benefits, and applications.

Introduction to Excavators

At the heart of construction projects, you’ll find these mighty machines—excavators. Their primary role is to excavate and manipulate the earth, but they are versatile enough to handle various other tasks such as loading, lifting, and demolishing.

The Importance of Excavators in Construction

Excavators serve as the backbone of construction projects, allowing the completion of tasks that would be prohibitively labor-intensive or even impossible without their assistance. These machines play a pivotal role in urban development, road construction, and various building projects.

Hydraulic Excavators

How Hydraulic Excavators Work

Different Types of Excavators: A Comprehensive Guide.Hydraulic excavators are the workhorses of the construction and excavation industry. Different Types of Excavators are marvels of engineering, using hydraulic systems to perform a wide range of tasks with precision and efficiency. In this detailed explanation, we will explore how hydraulic excavators work, from the fundamental principles of hydraulics to the intricate components that make them so versatile.

The Basics of Hydraulic Systems

At the core of a hydraulic excavator’s operation is a hydraulic system. This system relies on the principles of fluid dynamics to transmit force from one point to another. Here’s how it works:

1. Hydraulic Fluid

Hydraulic fluid, typically oil, is stored in a reservoir. This fluid is the lifeblood of the hydraulic system, as it is responsible for transmitting force when pressurized.

2. Pumping Action

The hydraulic system includes a pump that pressurizes the hydraulic fluid. This pressurization creates potential energy in the fluid, which can then be harnessed to perform work.

3. Valves and Control

Different Types of Excavators: A Comprehensive Guide.Control valves, often operated by the excavator’s operator, regulate the flow of hydraulic fluid. By controlling the opening and closing of these valves, the operator can direct the flow of fluid to different parts of the machine.

4. Actuators

Actuators, such as hydraulic cylinders, are the components that convert the pressurized hydraulic fluid’s energy into mechanical force. This force is what powers the various movements of the excavator, including the boom, arm, and bucket.

Movement of the Excavator

1. Boom and Arm Movement

Different Types of Excavators: A Comprehensive Guide.The boom and arm of the hydraulic excavator are responsible for reaching and digging. When the operator triggers these movements, the control valves adjust the flow of hydraulic fluid to the corresponding hydraulic cylinders. The pressurized fluid pushes or pulls the cylinders, extending or retracting the boom and arm as needed.

2. Bucket Operation

The bucket, attached to the end of the arm, plays a crucial role in excavating. The operator controls the bucket’s movement through hydraulic cylinders. The hydraulic fluid’s force powers the bucket’s motions, allowing it to dig into the earth, lift materials, and dump them into a truck or pile.

3. Swinging Motion

The rotating platform, or house, of the excavator is capable of 360-degree rotation. This rotation is achieved by hydraulic motors that turn the platform. The operator can smoothly control this motion, allowing precise positioning of the excavator.

4. Traveling

Different Types of Excavators: A Comprehensive Guide.To move the excavator from one location to another, hydraulic motors are used to drive the wheels or tracks. By manipulating the flow of hydraulic fluid to these motors, the operator can control the machine’s speed and direction.

Advantages of Different Types of Excavators

The use of hydraulic systems in excavators offers numerous advantages:

1. Power and Precision

Hydraulic excavators are known for their incredible power and precision. The hydraulic system can generate high forces, allowing these machines to handle even the toughest materials and excavation tasks with ease. The fine control over hydraulic flow enables operators to perform delicate maneuvers as well.

2. Versatility

Hydraulic excavators are incredibly versatile. Their wide range of attachments, from buckets for digging to grapples for handling materials, makes them suitable for a variety of tasks in construction, demolition, and more.Different Types of Excavators: A Comprehensive Guide.

3. Efficiency

Hydraulic systems are highly efficient in transmitting power. This means that hydraulic excavators can perform a significant amount of work while consuming relatively less fuel compared to other types of machinery.

4. Smooth Operation

Hydraulic systems provide smooth and proportional control. Operators can precisely control the speed and force of movements, ensuring that the machine responds accurately to their commands.

Maintenance and Care

Proper maintenance is essential to keep hydraulic excavators running smoothly. Routine checks, hydraulic fluid replacement, and occasional repairs are necessary to prevent downtime and ensure the longevity of the machine.

In conclusion, hydraulic excavators are remarkable pieces of machinery that rely on hydraulic systems to perform a wide array of tasks with precision and power. Understanding the principles of hydraulics and the intricate workings of these excavators is essential for both operators and those interested in the construction and excavation industry. Their versatility and efficiency continue to make them a fundamental part of modern construction and excavation operations.Different Types of Excavators: A Comprehensive Guide.

Advantages of Hydraulic Excavators

- Unmatched power and digging force

- Smooth and precise operation

- Adaptability to a wide range of tasks

Crawler Excavators

Crawler excavators are designed with tracks, making them well-suited for navigating challenging terrains. These machines find extensive use in demanding sectors such as mining, forestry, and heavy-duty construction.

Features and Benefits of Crawler Excavators

- Exceptional stability and mobility

- Reduced ground pressure, minimizing environmental impact

- Excellent traction on rough or uneven surfaces

Wheeled Excavators

In contrast to their tracked counterparts, wheeled excavators are fitted with wheels, enhancing their mobility on roads and highways. This characteristic makes them ideal for urban construction and utility work.

Advantages of Wheeled Excavators

- Faster on-road travel

- Suitable for shorter-distance jobs

- Ideal for maneuvering in urban environments

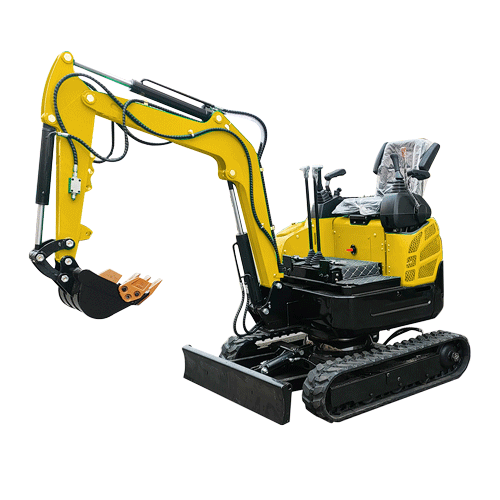

Mini Excavators

Mini excavators, characterized by their compact size and high maneuverability, are the perfect choice for smaller projects, landscaping, and residential construction.Different Types of Excavators: A Comprehensive Guide.

Uses and Applications of Mini Excavators

- Digging trenches and foundations

- Landscaping tasks like grading and digging small ponds

- Residential construction projects, such as digging swimming pool foundations

Backhoe Loaders

Backhoe loaders, a versatile combination of a loader and a backhoe, are capable of a wide range of tasks. They are adept at digging, scooping, and loading materials, making them invaluable for urban and rural projects.

Versatility of Backhoe Loaders

- Excavating trenches and ditches

- Loading and transporting materials

- Demolition work

Long Reach Excavators

Long reach excavators are equipped with extended arms, allowing them to reach greater depths and heights. These machines are frequently used in dredging, canal maintenance, and deep excavation projects.

Applications in Specialized Projects

- Dredging rivers and waterways

- Canal maintenance and deep excavation

- Reach challenging locations in construction

Amphibious Excavators

Different Types of Excavators: A Comprehensive Guide.Amphibious excavators are specially designed for working in wet and swampy conditions. They excel in tasks such as dredging, environmental restoration, and waterway maintenance.

Unique Capabilities of Amphibious Excavators

- Floating on water, allowing work in swamps and marshes

- Ideal for maintaining aquatic ecosystems

- Efficient in cleaning water bodies and restoring wetlands

Excavator Attachments

Excavator attachments play a crucial role in enhancing their versatility. Augers are used for drilling, buckets for digging, and grapples for lifting and carrying various materials, expanding the scope of their applications.

Maintenance and Care of Excavators

Ensuring the longevity and optimal performance of excavators requires regular maintenance and care. This includes lubrication, inspections, and timely repairs to prevent downtime.

Safety Measures for Excavator Operation

Operational safety is paramount when working with excavators. Proper training, adherence to safety protocols, and regular equipment maintenance are essential to prevent accidents and ensure a safe working environment.

Excavators in Environmental Conservation

Beyond construction, excavators play a significant role in environmental projects, including wetland restoration and habitat creation. Their versatility extends to preserving and restoring ecosystems, showcasing their importance in sustainable practices.Different Types of Excavators: A Comprehensive Guide.

Future Trends in Excavator Technology

The future of excavators promises exciting developments, including enhanced fuel efficiency, autonomous operation, and environmentally sustainable features. As technology advances, the construction industry will see more efficient and eco-friendly excavators.

Conclusion

In conclusion, excavators are the unsung heroes of the construction world. Their wide range of types and applications make them indispensable for countless tasks, from urban development to environmental conservation. Understanding the different types and their capabilities is crucial for those in the construction industry.

Frequently Asked Questions

Are excavators only used in construction?

No, excavators have a wide range of applications, including mining, forestry, environmental conservation, and more.

What is the difference between hydraulic and mechanical excavators?

Hydraulic excavators use hydraulic fluid to power their movements, providing precision and control. Mechanical excavators are operated manually.

Can mini excavators handle heavy-duty tasks?

While mini excavators are compact, they are equipped to handle a variety of tasks, including landscaping and residential construction.

How can I ensure the safety of excavator operations?

Safety in excavator operations involves proper training, adherence to safety protocols, and regular maintenance.

What are the emerging trends in excavator technology?

The future of excavators includes advancements in fuel efficiency, autonomous operation, and environmentally friendly features.