Introduction

The construction industry is a dynamic and ever-evolving field, constantly seeking innovative solutions to enhance efficiency, safety, and sustainability. In recent years, tracked mini dumpers have emerged as game-changers in the construction landscape, offering a versatile and powerful alternative to traditional wheeled dumpers. These compact yet robust machines are revolutionizing material handling operations across a wide range of construction projects.

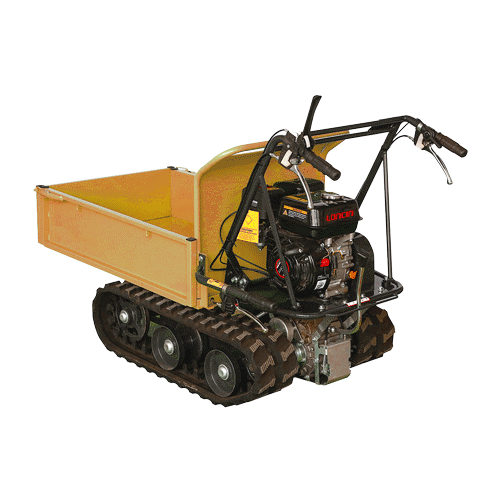

Anatomy of a Tracked Mini Dumper

Small crawler dump trucks, also known as tracked dumper carriers or mini tracked skid steers, are designed to excel in challenging environments where maneuverability, traction, and ground pressure are critical. Their unique design features set them apart from wheeled dumpers, making them ideal for a variety of construction applications:

Tracked Undercarriage: The tracked undercarriage replaces wheels with continuous rubber or steel tracks, providing superior traction and stability on uneven, soft, or loose terrain.

Compact Size: Tracked mini dumpers are significantly smaller and lighter than traditional wheeled dumpers, allowing them to navigate tight spaces, operate in confined areas, and minimize damage to delicate surfaces.

High Dumping Height: Despite their compact size, tracked mini dumpers offer impressive dumping heights, enabling them to reach over obstacles and discharge materials into elevated positions.

Articulated Steering: Articulated steering allows for exceptional maneuverability, enabling tracked mini dumpers to turn on a dime and navigate around obstacles with ease.

Versatile Attachments: Tracked mini dumpers can be equipped with a variety of attachments, expanding their functionality beyond material handling to include tasks like trenching, drilling, and snow removal.

Advantages of Tracked Mini Dumpers in Construction Projects

Small crawler dump trucks offer a multitude of advantages over traditional wheeled dumpers, making them a valuable asset in a wide range of construction projects:

Superior Traction and Stability: The tracked undercarriage provides exceptional traction on uneven, soft, or loose terrain, ensuring stability and preventing tipping, even on slopes and inclines.

Reduced Ground Pressure: The weight of the tracked mini dumper is distributed over a larger area, minimizing ground pressure and preventing damage to delicate surfaces like lawns, landscaping, and paved areas.

Enhanced Maneuverability: The compact size and articulated steering allow for exceptional maneuverability in tight spaces, enabling tracked mini dumpers to navigate around obstacles, operate in confined areas, and reach difficult-to-access locations.

Versatility and Adaptability: Tracked mini dumpers can be equipped with a variety of attachments, transforming them into multi-purpose machines capable of handling tasks like trenching, drilling, snow removal, and site cleanup.

Reduced Environmental Impact: The combination of reduced ground pressure, minimized emissions, and lower noise levels makes tracked mini dumpers a more environmentally friendly option compared to traditional wheeled dumpers.

Table: Comparison of Tracked Mini Dumpers to Wheeled Dumpers

| Feature | Tracked Mini Dumper | Wheeled Dumper |

|---|---|---|

| Traction | Superior on uneven, soft, or loose terrain | Limited on uneven or soft terrain |

| Stability | Stable on slopes and inclines | Prone to tipping on uneven or soft terrain |

| Ground Pressure | Minimized | Higher ground pressure, potential damage to delicate surfaces |

| Maneuverability | Excellent in tight spaces and confined areas | Limited in tight spaces and confined areas |

| Versatility | Can be equipped with a variety of attachments | Limited to material handling |

| Environmental Impact | Reduced ground pressure, lower emissions, lower noise levels | Higher ground pressure, higher emissions, higher noise levels |

Conclusion

Tracked mini dumpers have revolutionized material handling operations in the construction industry, offering a versatile, maneuverable, and environmentally friendly solution for a wide range of projects. Their superior traction, stability, and ground pressure make them ideal for challenging terrains, while their compact size and articulated steering enable them to navigate tight spaces and operate in confined areas. With their ability to be equipped with a variety of attachments, tracked mini dumpers transcend the limitations of traditional wheeled dumpers, transforming into multi-purpose machines capable of handling diverse tasks. As the construction industry continues to embrace innovation and sustainability, tracked mini dumpers are poised to play an increasingly prominent role in shaping the future of construction projects.

FAQ

Are small crawler dump trucks suitable for use in all weather conditions?

Tracked mini dumpers are designed to perform well in various weather conditions, including rain, snow, and mud. However, operators should exercise caution and adjust their operating techniques accordingly to ensure safe operation in adverse weather conditions.

Can Small crawler dump trucks be equipped with additional attachments for specific tasks?

Yes, small crawler dump trucks can be equipped with a variety of attachments, such as buckets, forks, and grapples, to accommodate different construction tasks and applications. These attachments enhance the versatility and functionality of tracked mini dumpers, allowing them to perform a wider range of tasks on construction sites.

What maintenance tasks are required for small crawler dump trucks?

Maintenance tasks for tracked mini dumpers typically include regular inspections of tracks, undercarriage components, and hydraulic systems, as well as lubrication of moving parts and cleaning of filters. It’s essential to follow the manufacturer’s maintenance schedule and recommendations to ensure optimal performance and longevity of the equipment.

How does the cost of owning and operating a tracked mini dumper compare to a wheeled dumper?

The cost of owning and operating a tracked mini dumper may be slightly higher than that of a wheeled dumper initially due to the higher upfront purchase cost and potentially higher maintenance expenses. However, tracked mini dumpers often offer lower long-term operating costs due to their durability, efficiency, and versatility, resulting in a favorable return on investment over time.

Are there any safety considerations when operating tracked mini dumpers?

Yes, safety is paramount when operating tracked mini dumpers. Operators should undergo proper training on equipment operation and safety procedures to prevent accidents and injuries. It’s essential to observe load capacity limits, maintain proper balance when dumping loads, and use caution when operating on slopes or uneven terrain. Additionally, wearing appropriate personal protective equipment (PPE) and following all safety guidelines outlined in the equipment manual are essential for safe operation.