In today’s construction and mining industry, heavy-duty machinery plays a pivotal role in accomplishing tasks that would otherwise be impossible for human workers alone. Among the most impressive of these machines are “super excavators,” colossal giants designed to conquer the toughest terrains, excavate massive quantities of earth, and reshape the landscape. In this article, we delve into the world of super excavators, exploring their functions, features, and the innovations that make them the titans of the earth-moving industry.

Introduction

Super excavators, often simply referred to as “excavators,” are colossal machines engineered for the most challenging tasks on earth. These mechanical marvels are the unsung heroes behind our modern infrastructure and resource extraction efforts. In this article, we will unravel the secrets behind these hulking giants and explore the critical roles they play in construction, mining, and more.

Evolution of Excavators

The journey of super excavators begins with their ancestors, which were significantly smaller and less powerful. Over the decades, technological advancements have led to the birth of the super excavator we know today. Their history is a testament to human innovation and our unyielding quest to conquer the earth.

Anatomy of Super Excavators

The Powerhouse Engine

At the heart of every super excavator lies a powerful engine that provides the necessary torque and horsepower to drive these behemoths. These engines are designed to deliver optimal performance while minimizing emissions.

Hydraulic Systems

Super excavators rely on intricate hydraulic systems to control their movements. These systems allow for precise and agile operations, ensuring that excavators can handle a variety of tasks with ease.

Bucket and Boom

The bucket and boom of a super excavator are the business end of these machines. The bucket can be equipped with various tools, such as a shovel or a grapple, making them versatile earth movers. The boom, on the other hand, provides reach and flexibility.

Types of Super Excavators

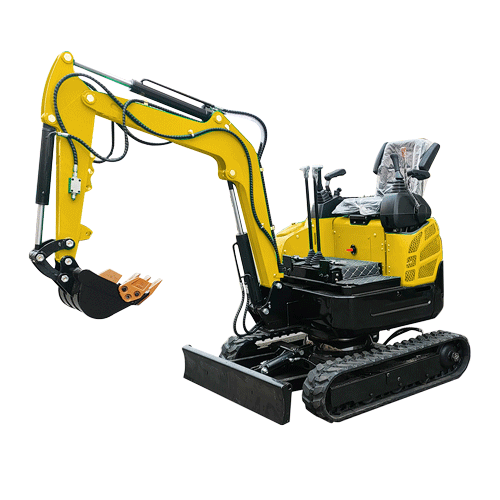

Crawler Excavators

Crawler Excavators are powerful machines used in construction and earthmoving. They have tracks that allow them to move across challenging terrains. The primary components of a Crawler Excavator include the undercarriage, boom, arm, and bucket. The undercarriage has tracks with rollers, idlers, and sprockets. These tracks provide stability and enable the excavator to navigate uneven landscapes.

The boom, arm, and bucket constitute the upper structure. The boom extends vertically, and the arm offers horizontal reach. The bucket, attached to the arm, performs excavation and material handling. The operator’s cabin is situated on the upper structure, providing a comfortable and climate-controlled environment for the operator. Inside the cabin, controls, joysticks, and digital displays allow for precise operation.

Crawler Excavators are versatile and widely used for various tasks. They excel in earthmoving and excavation, making them essential for projects, both large and small. Their ability to dig deep trenches and foundations is invaluable. Furthermore, these machines are adaptable for demolition work. Attachments like hydraulic hammers and shears enable them to break down concrete and other materials.

The versatility of Crawler Excavators extends to material handling. By swapping out the standard bucket for various attachments like grapples and forks, they can handle a wide range of materials. Loading trucks and sorting materials on a construction site are tasks they excel at.

These machines are also adept at grading and landscaping. With specialized grading attachments, they can accurately shape landscapes and roads. This precision is crucial in road construction, landscaping, and creating even surfaces. Additionally, Crawler Excavators are used for lifting and placing heavy objects. Attachments like lifting hooks allow them to hoist and position beams, pipes, and other bulky materials.

Hydraulic systems are at the core of Crawler Excavators. They control the movement of various components, providing precision and control to operators. Robust engines power these hydraulic systems, ensuring the necessary power to move the excavator and operate attachments. Diesel engines are common, offering high torque and fuel efficiency. However, manufacturers are exploring electric and hybrid systems to reduce emissions and fuel consumption.

Crawler Excavators come in different sizes. Compact models are ideal for tight spaces, while mid-sized ones strike a balance between power and agility. Large Crawler Excavators are heavy-duty and suitable for major construction projects, mining operations, and industrial applications. Their size and power vary, making them suitable for a broad spectrum of projects.

The advantages of Crawler Excavators include superior stability due to their tracked undercarriage. This stability is vital when working on uneven terrain or during heavy lifting operations. Their hydraulic systems provide precise control, allowing for delicate and accurate movements, even in challenging tasks. The ability to switch between a wide range of attachments makes Crawler Excavators versatile and adaptable to changing project requirements. They are built to withstand demanding conditions, known for their longevity and reliability, reducing downtime and maintenance costs.

Wheeled Excavators

Wheeled excavators are more mobile, making them ideal for urban construction projects. They are equipped with wheels and are easier to transport from one location to another.

The Super Excavator’s Playground

Super excavators are found in various industries, but they primarily dominate construction sites and mining operations. They are the muscle behind building skyscrapers and extracting valuable resources from the earth.

Challenges and Innovations

Working in Extreme Conditions

Super excavators often work in extreme conditions, from scorching deserts to freezing tundras. Innovative cooling and insulation technologies ensure that these machines can operate efficiently in any environment.

Fuel Efficiency and Sustainability

As environmental concerns grow, super excavators are becoming more fuel-efficient and environmentally friendly. Advancements in engine technology and alternative fuels are contributing to a greener future for these giants.

Driving the Super Excavator

Operating a super excavator requires skill and precision. Experienced operators are in high demand and undergo rigorous training to ensure they can handle these powerful machines safely and efficiently.

Safety Measures and Training

Safety is paramount in the world of super excavators. Rigorous training, strict safety protocols, and cutting-edge technology work hand in hand to protect both operators and bystanders.

Maintenance and Longevity

Regular maintenance is essential to extend the lifespan of super excavators. This includes routine inspections, lubrication, and timely replacement of worn-out parts.

The Future of Super Excavators

The future of super excavators is bright. With ongoing research and development, we can expect these machines to become even more efficient, environmentally friendly, and versatile in their applications.

Cost Considerations

Owning and operating a super excavator is a substantial investment. We explore the various cost considerations and factors that make these machines worth every penny.

Environmental Impact

As society becomes more environmentally conscious, super excavators are adapting to reduce their ecological footprint. We discuss the efforts being made to minimize the environmental impact of these heavy-duty machines.

Applications Beyond Earth

Super excavators aren’t confined to our planet. They play a role in space exploration, helping dig, drill, and collect data on other celestial bodies, expanding the limits of human understanding.

Conclusion

Super excavators are the unsung heroes of modern engineering and industry. Their sheer power, versatility, and adaptability make them indispensable in construction, mining, and even space exploration. As we move forward, we can expect even more incredible innovations in the world of super excavators, cementing their place as marvels of human engineering.

Frequently Asked Questions (FAQs)

1. What is the largest super excavator in the world?

- The largest super excavator is the Bucyrus RH400, which can weigh up to 980 metric tons.

2. How do super excavators impact the environment?

- Super excavators can have environmental impacts, but advancements in technology are making them more eco-friendly with reduced emissions and fuel consumption.

3. What are the career prospects for super excavator operators?

- Operating super excavators can be a lucrative career, with high demand for skilled operators in construction and mining industries.

4. Can super excavators work in extreme weather conditions?

- Yes, super excavators are equipped to work in extreme conditions, thanks to advanced cooling and insulation technologies.

5. Are there any plans to use super excavators in space exploration?

- Yes, super excavators have been considered for use in space exploration missions to dig, drill, and gather data on other celestial bodies.